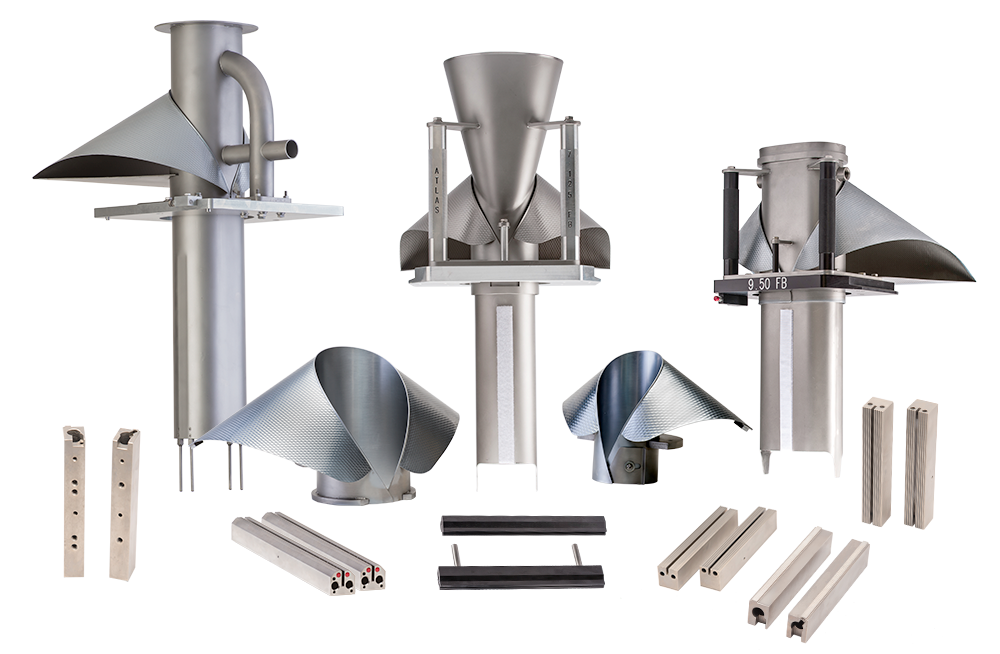

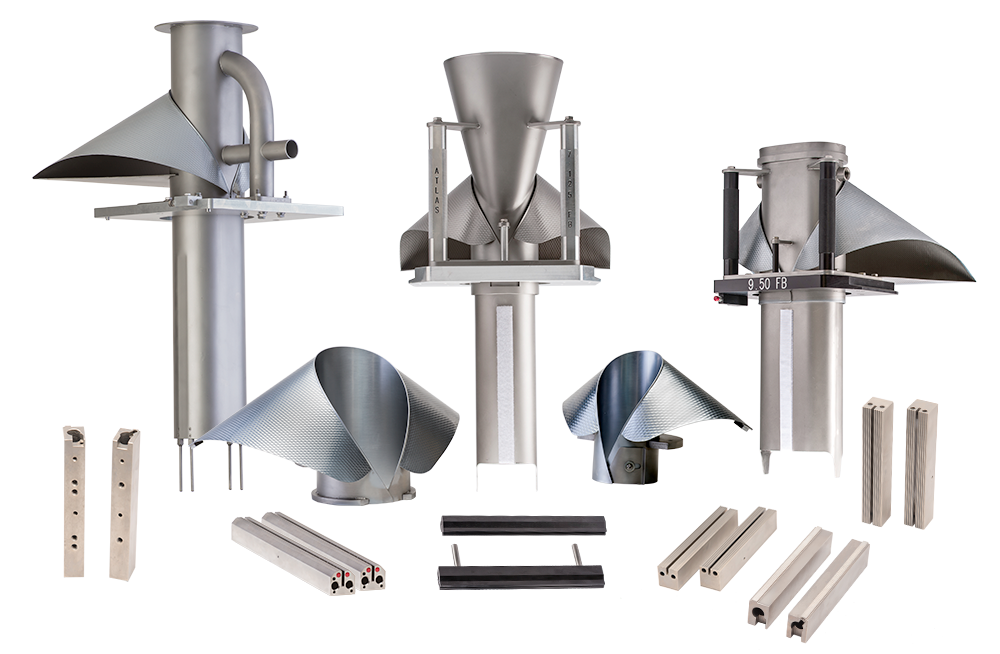

Former Fab is the best solution for forming shoulders and sealing jaws.

Former Fab fabricates VFFS forming tubes & sealing jaws for every type of horizontal and vertical form fill seal machine.

We maintain quality control throughout the design and construction process to ensure that your forming unit is built to the highest quality standards. Computer-aided 3D design software allows us to visualize the final product before production to ensure correct fabrication.

Flexible delivery times to accommodate your production schedule. Every unit is custom crated for problem-free shipping.

Packaging machines have a lot of moving parts, and if just one part needs to be replaced, it can take a whole production line down with it. That results in lost time and business for you, and we don’t want that to happen. Former Fab offers our clients reverse-engineering for obsolete and high consumption parts.

Former Fab fabricates custom all-metal solutions and offers a wide variety of materials, fabrication, and finishing services to produce your project to your specifications. Want to revise, rework, or just experiment with new equipment? Our design team is equally experienced using our customers’ designs as-is, or providing research and development input from concept to product realization.

We can provide onsite machine repair, welding, and employee training services to keep your machines running and your staff fully trained on maximizing your machines’ capabilities.

Our clients know where to go for true value. Whether it’s new fabrication, or refurbishing the “tried and true”, Former Fab can help you get maximum use out of the equipment you have already invested in.

We supply parts, inventory management, custom and emergency manufacturing, and onsite machine repair and training to minimize your downtime.

Former Fab Inc.’s founder, Dennis Kokkinis has more than 30 years of experience in the engineering and fabrication of vertical, form fill and seal (VFFS) tooling. This unmatched experience has led to lifelong relationships with some of the biggest food packagers and OEM packaging machine suppliers in the world. All of our customers receive this same care, attention, unbeatable quality and value regardless of the size of their operation.

We work closely with our clients to seek continuous improvement using innovative techniques and materials. For example, we created Duralyte, a unique product that combines the best innovations in lightweight materials and toughness of service. Our proprietary Duralyte formers are up to 40% lighter than our traditional formers, but just as durable. These forming assemblies are designed on our 3D software program that allows us to remove material in strategic locations without compromising rigidity.

We have built our sterling reputation on the concept of “Customer First, 24/7 Support”. We test every unit to assure your packages will be formed and sealed perfectly.

We maintain quality control throughout the design and construction process to ensure that your forming unit be built to the highest quality standards. Computer-aided 3D design software allows us to visualize the final product before production to ensure correct fabrication. When you choose Former Fab, Inc. for your bagger tooling you are guaranteed that your order will be processed fast, shipped on time, delivered safely in custom-built packaging and work perfectly upon installation.

We supply the absolute best quality forming assemblies and sealing jaws for all brands and applications at the best prices.