Horizontal, vertical and diagonal standard serrations

FORMING SHOULDERS

Our formers provide precise film tracking, balance, and high product transfer speed. Our proprietary Duralyte formers are up to 40% lighter than our traditional formers, but just as durable. These forming assemblies are designed on our 3D software program that allows us to remove material in strategic locations without compromising rigidity.

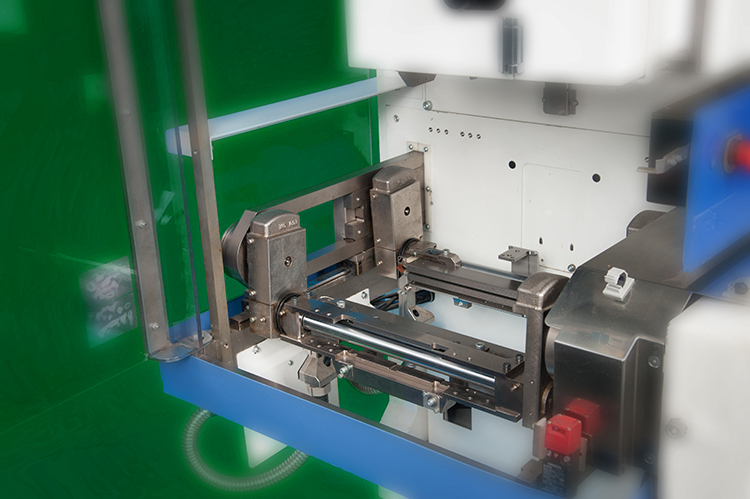

CUSTOM METAL FABRICATION

Former Fab fabricates custom all-metal solutions and offers a wide variety of materials, fabrication, and finishing services to produce your project to your specifications. Whether it’s new fabrication, or refurbishing the “tried and true”, Former Fab can help you get maximum use out of the equipment you have already invested in.

OUR FACILITY

We are proud to announce the completion of our 30,000-square-foot facility for design, development and product testing at the Former Fab Business Park at 2101 Former Fab Drive on five acres in Pearland, Texas. This enlarged footprint has superb access and allows us to continue growing in step with our customers and accommodate our expanding support role capabilities.

WHAT OUR CLIENT SAY

We believe that the best testimonial comes from the fact the Former Fab enjoys one of the highest client retention rates in the industry. Once a Former Fab customer, always a Former Fab customer! However, if you’d like to know more about what Former Fab can do, take a look a what our customers say!